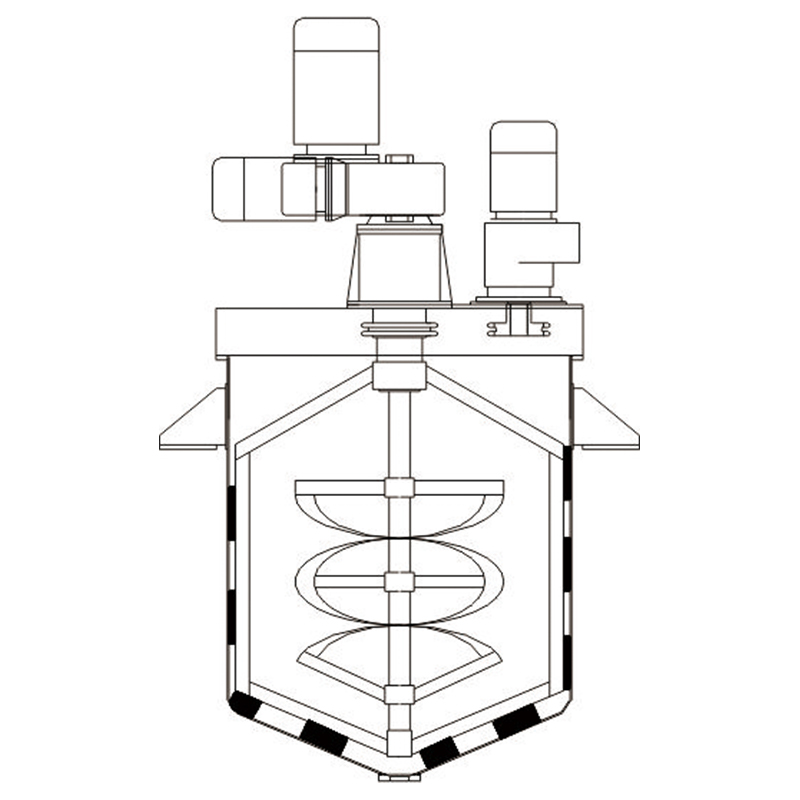

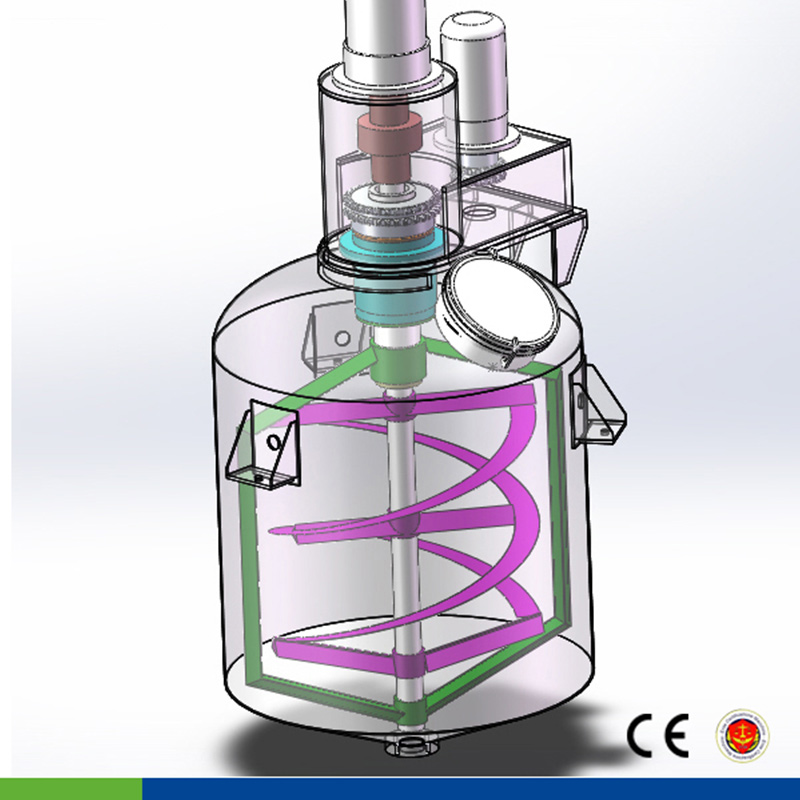

Daily Chemical Care Products Making Machine Vacuum Emulsifying MixerOEM&ODM SERVICE(Turn-key project)Vacuum homogenizer for making body cream lotion, face ceam, hand cream, cosmetics paste etcDaily Hand Cream Cosmetic Lotion Vacuum Homgoenizer Mixing Making MachineIn the high viscosity of emulsion, especially the manufacturing process of cream, ointment, emulsion products, usually the most problematic is the dispersed phase particle size and mixing the air mixed with products, grain size is too large a everywhere emulsion instability, lack luster; products into the air will make the products bubble, bacterial contamination, easy oxidation and the appearance is not smooth. For the two in question, our developed YIF series vacuum emulsifying mixer , by the quality agitator blade mixing, scraping the wall, the center has stirred theirplement each other, arebined into a mixing the best way, to achieve the perfect mixed products. The color and the vacuum pumping mode, so that the production for export in the mixing process of no air bubbles, which can produce shiny, delicate and good ductility of high quality products.Daily Chemical Care Products Making Machine Vacuum Emulsifying MixerIn the process of producing emulsion with high viscosity, there are two important problems.One is the scattered bigger diameter e other is the air which will mix into the material during the mixing. Particles of the large diameter will lead to the labile state of the materials. If the air goes into the material, the material will be mixed with bubble, polluted by bacterium, easily oxidized and obtained an rough appearance .Regarding to these two problems, our factory-YALIAN vacuum emulsifying mixer manufacturer had developed YIF Vacuum Emulsifying Mixer which are made up of homogenizer & middle blade stirrer & scraper residues stirrer to form the best mixing way in order to produce the perfect mixed material. By extracting air from the material, the vacuum pump can ensure that the material is glossy, exquisite and ductile.Working Elements of vacuum emulsifying mixer machine:After the materials are heated & mixed in water pot and oil pot, they are drawn into the emulsifying boiler by the vacuum pump. Adopting the middle stirrer & scrapers, the emulsifying boiler can sweep the residues on the wall of the boiler. Then the materials are cut off,pressed and folded by the blades. By the strong cutting off force and the impact and turbulent current from the high-speed shear wheel and fixed cutting case, the materials are cut off and turned to particles of 200 nm- 2 um promptly. Because the emulsifying boiler is under vacuum state, the bubbles that are produced in the course of mixing will be taken away in time.Daily Chemical Care Products Making Machine Vacuum Emulsifying MixerDaily Chemical Care Products Making Machine Vacuum Emulsifying MixerHomogenizer motorStir motorVacuum pumpHeating powerkWr/minkWr/minkWLimit vacuumElectric heatingSteam heatingYIF-1.0962YIF-2.0993YIF-5.09124YIF-3.5-0.09249YIF-3.5-0.09249YIF-200.2-0.092810YIF-300.2-0.0853212YIF-500.0855016YIF-3-0.086525YIF-500.0853212YIF-3-0.086525YIF-3-0.086525YIF-3.5-0.087243YIF.5-0.089063(The parameters are for reference only,the product depend on actual items.)Homogenizer Machine PLC Control Type Cosmetic Cream Making MachineFeatures of vacuum emulsifying mixer:The pot cover is of automatic rising type. The material is directly drawn into the emulsifying boiler from oil boiler and water boiler. The discharge is based on the turning of the emulsifying boiler. And the heating system is electric heating and steam heating by the heating pipe, so the temperature is controlled automatically. Put the cool water into the intercalated bed so as to cool the material, which is simple and convenient (there is a warm layer outside the intercalated bed). The homogenizer and the stirring blades can work together or separately. The material sliming, emulsification, mixing, dispersing, etc. can be finished in a short time. Some parts of the vacuum emulsifying machine are made of high-quality stainless steel (316L material will be adopted for medical use; the interior surface adopts mirror polish, vacuum agitating device is hygienically made according to the normal hygiene standard of GMP and is the most idea production equipment).Homogenizer Machine PLC Control Type Cosmetic Cream Making MachineProducts detailsYALIAN Factory wax making machines priceFinal productDaily Chemical Care Products Making Machine Vacuum Emulsifying MixerMachining drawingDaily Chemical Care Products Making Machine Vacuum Emulsifying MixerFa specialized in design, manufacturing, installation andmissioning of daily chemical, chemical, food and pharmaceutical machinery, as well as water treatment equipment. With powerful technical strength,plete inspection facilities, unique and advanced technique as well as great varieties of products, the enterprise strictly implements ISO9001 standard management.Daily Chemical Care Products Making Machine Vacuum Emulsifying MixerDaily Chemical Care Products Making Machine Vacuum Emulsifying MixerR is one of the .2. Q: I am new in this field , can you rmend the whole production line?A: We can rmend you the whole production line depends on what products you will make:(1). If forpaste or cream product, the following machine we will rmend you:RO water treatment equipment→Vacuum homogenizer→Storage tank→Paste filling machineorHeating mixing filling machine→Capping machine→Labeling machine→Inkjet printer→Shrink film packing machineetc.,(2). If forliquid product, the following machine we will rmend you:RO water treatment equipment→Blending tank→Storage tank→Liquid filling machine→Capping machine→Labeling machine→Inkjet printer→Shrink film packing machineetc.,(3). If forPerfume, the following machine we will rmend you:RO water treatment equipment→Perfume making machine→Perfume storage tank→Perfume filling machine→Perfume crimping machine→Perfume collar machine→Inkjet printer→Shrink film packing machineetc.,(4). There areFull automatic production lineandSemi automatic production linefor your option.3. Q: What is your payment term?A: We usually pay by T/T., 40% deposit after sales confirmation, 60%before delivery.4. Q: What is your delivery day?A: Our delivery day is about days after receive the deposit. THa66ZoMgOTA CE approved cosmetic cream blending machine for body lotion homogenizersProduct ShotsLifting type vacuum emulsifier mixer homogenizer with oil and water potsSS316L mixing system with PTFE scraper-Mixing speed is 0-60rpm, it can be adjusted with inverter.Oil and water phase boilers -Dispersion blending speed can be up to 1440rpmFeatures1. Vacuum defoaming function can make the materials meet the requirement of being aseptic.2. The main boiler lid adopts the lifting system, it is easy to clean and the cleaning effect is more obvious, the main boileradopts a tilting discharge.3. The main tank can be heated and cooled with an electric heating function.4. Adopts imported electric appliances which can meet international standards.5. Contacted parts are made of SS316LWall scraper mixerHomogenizerWater and oil potDisperser50L1.1kw, 0-65rpm2.2kw, 0-3600rpm45/30L0.37/0.37kw, 1440rpm100L1.5kw, 0-65rpm4kw, 0-3600rpm90/60L0.55/0.55kw, 1440rpm200L3kw, 0-65rpm5.5kw, 0-3600rpm180/120L0.75/0.75kw, 1440rpm300L4kw, 0-65rpm7.5kw, 0-3600rpm270/180L1.1/1.1kw, 1440rpm500L5.5kw, 0-65rpm11kw, 0-3600rpm450/300L1.5/1.5kw, 1440rpmApplicationWhat can we do?We can provide you with excellent production lines and packing solutions, pl; 2. Your produ ProfileFAQ1. Can you customize the volume for the vacuum emulsifier?Yes, we can do it. But it will take much more time to customize it. The production time for standard machine is about 30 working days.2. Which parts can you customize?Such as mixer/homogenizer motor, mixing paddle, layer, heating method, control type(PLC/Button), electric box, volume, etc. It depends on your requirements.3. What functions does the machine have?Such as vacuum defoaming, heating, cooling, mixing, emulsifying, high shear homogenizing, lifting, auto discharge, auto cleaning,etc.4. What products can this machine produce?Cosmetics: face cream, lotion, serum, body butter, liquid foundation, sunscreen cream, od: mayonnaise, ketchup, source, etc.Daily chemical: shampoo, conditioner, hair essential oil, toothpaste, liquid soap, detergent, etc.5. What is the function of oil/water tank?Good question! Its function is pre-heating/pre-process. The semi-finished products will be transferred to the main tank formixing. If you want to buy vacuum emulsifier with small volume, so we don't rmend you to equip them.6. What is the brand for the motor of vacuum emulsifier?Normally we use the Siemens Motor, sometimes it's difficult to order the Siemens motor, so our client will also choose ABB motor.7. Can you also customize the power supply?Yes, that's no problem. The standard power supply for the vacuum emulsifier is 3P/380V, we can customize the voltage based on your requirements. Such as 3P/220V, 1P/220V, 1P/110V, 3P/415V, etc. To be told, the production time will be longer if we customize it.8. Please let me know the material used, ok?The contacted part is made of SS316L, and the machine body is made of SUS304.9. I am a starter in the cosmetic field, and I want to rent a factory to start it, what suggestions will you provide us?For starters, we rmend that you can choose 50L or 100L small vacuum emulsifier, semi-auto filling machine, and capping machine. When your business be bigger, you can buy the automatic machine. Anyway, please let me know your specific requirements, such per day. It will be better if you can let us know your budget.10. Can you let me know the speed for the motors?We equip the inverters, the speed of mixing motor is 0-63rpm, the speed of homogenizing motor is 0-3000rpm, which means the speed can be adjusted easily. aMvnu7wJSs3M YALIAN Factory wax making machines priceOEM&ODM SERVICE(Turn-key project)Vacuum homogenizer for making body cream lotion, face ceam, hand cream, cosmetics paste etcDaily Hand Cream Cosmetic Lotion Vacuum Homgoenizer Mixing Making MachineIn the high viscosity of emulsion, especially the manufacturing process of cream, ointment, emulsion products, usually the most problematic is the dispersed phase particle size and mixing the air mixed with products, grain size is too large a everywhere emulsion instability, lack luster; products into the air will make the products bubble, bacterial contamination, easy oxidation and the appearance is not smooth. For the two in question, our developed YIF series vacuum emulsifying mixer , by the quality agitator blade mixing, scraping the wall, the center has stirred theirplement each other, arebined into a mixing the best way, to achieve the perfect mixed products. The color and the vacuum pumping mode, so that the production for export in the mixing process of no air bubbles, which can produce shiny, delicate and good ductility of high quality products.Daily Hand Cream Cosmetic Lotion Vacuum Homgoenizer Mixing Making MachineIn the process of producing emulsion with high viscosity, there are two important problems.One is the scattered bigger diameter e other is the air which will mix into the material during the mixing. Particles of the large diameter will lead to the labile state of the materials. If the air goes into the material, the material will be mixed with bubble, polluted by bacterium, easily oxidized and obtained an rough appearance .Regarding to these two problems, our factory-YALIAN vacuum emulsifying mixer manufacturer had developed YIF Vacuum Emulsifying Mixer which are made up of homogenizer & middle blade stirrer & scraper residues stirrer to form the best mixing way in order to produce the perfect mixed material. By extracting air from the material, the vacuum pump can ensure that the material is glossy, exquisite and ductile.Working Elements of vacuum emulsifying mixer machine:After the materials are heated & mixed in water pot and oil pot, they are drawn into the emulsifying boiler by the vacuum pump. Adopting the middle stirrer & scrapers, the emulsifying boiler can sweep the residues on the wall of the boiler. Then the materials are cut off,pressed and folded by the blades. By the strong cutting off force and the impact and turbulent current from the high-speed shear wheel and fixed cutting case, the materials are cut off and turned to particles of 200 nm- 2 um promptly. Because the emulsifying boiler is under vacuum state, the bubbles that are produced in the course of mixing will be taken away in time.Daily Hand Cream Cosmetic Lotion Vacuum Homgoenizer Mixing Making MachineYALIAN Factory wax making machines priceHomogenizer motorStir motorVacuum pumpHeating powerkWr/minkWr/minkWLimit vacuumElectric heatingSteam heatingYIF-1.0962YIF-2.0993YIF-5.09124YIF-3.5-0.09249YIF-3.5-0.09249YIF-200.2-0.092810YIF-300.2-0.0853212YIF-500.0855016YIF-3-0.086525YIF-500.0853212YIF-3-0.086525YIF-3-0.086525YIF-3.5-0.087243YIF.5-0.089063(The parameters are for reference only,the product depend on actual items.)YALIAN Factory wax making machines priceFeatures of vacuum emulsifying mixer:The pot cover is of automatic rising type. The material is directly drawn into the emulsifying boiler from oil boiler and water boiler. The discharge is based on the turning of the emulsifying boiler. And the heating system is electric heating and steam heating by the heating pipe, so the temperature is controlled automatically. Put the cool water into the intercalated bed so as to cool the material, which is simple and convenient (there is a warm layer outside the intercalated bed). The homogenizer and the stirring blades can work together or separately. The material sliming, emulsification, mixing, dispersing, etc. can be finished in a short time. Some parts of the vacuum emulsifying machine are made of high-quality stainless steel (316L material will be adopted for medical use; the interior surface adopts mirror polish, vacuum agitating device is hygienically made according to the normal hygiene standard of GMP and is the most idea production equipment).YALIAN Factory wax making machines priceProducts detailsYALIAN Factory wax making machines priceFinal productYALIAN Factory wax making machines priceMachining drawingYALIAN Factory wax making machines priceFa specialized in design, manufacturing, installation andmissioning of daily chemical, chemical, food and pharmaceutical machinery, as well as water treatment equipment. With powerful technical strength,plete inspection facilities, unique and advanced technique as well as great varieties of products, the enterprise strictly implements ISO9001 standard management.YALIAN Factory wax making machines priceYALIAN Factory wax making machines priceR is one of the .2. Q: I am new in this field , can you rmend the whole production line?A: We can rmend you the whole production line depends on what products you will make:(1). If forpaste or cream product, the following machine we will rmend you:RO water treatment equipment→Vacuum homogenizer→Storage tank→Paste filling machineorHeating mixing filling machine→Capping machine→Labeling machine→Inkjet printer→Shrink film packing machineetc.,(2). If forliquid product, the following machine we will rmend you:RO water treatment equipment→Blending tank→Storage tank→Liquid filling machine→Capping machine→Labeling machine→Inkjet printer→Shrink film packing machineetc.,(3). If forPerfume, the following machine we will rmend you:RO water treatment equipment→Perfume making machine→Perfume storage tank→Perfume filling machine→Perfume crimping machine→Perfume collar machine→Inkjet printer→Shrink film packing machineetc.,(4). There areFull automatic production lineandSemi automatic production linefor your option.3. Q: What is your payment term?A: We usually pay by T/T., 40% deposit after sales confirmation, 60%before delivery.4. Q: What is your delivery day?A: Our delivery day is about days after receive the deposit. erzPX1IpzjEg Custom Made 50L- 10,000L, 20 Years Of Experience. Reasonable Price And Best Service, CE Certificated Products. Please contact us for the offer.Mixing tankse in various sizes and can be used in a wide range of industries.We are a manufacturer of stainless steel mixing tanks designed to fit your products and scription:This series is the most advanced blending equipment in fields of Chemical, pharmaceutical, food, etc. When the high-speed super-fine emulsification paddle works, it throws the materials in the center of rotor to stator at a high speed,then through tooth clearance of stator,and shearing,collision and crushing between rotor and stator,the super-fine emulsification is realized. therefore,it is an integrated equipmentprising functions such as blending,emulsifying,homogenizing,solving and crushing.We can customize according to your drawings, or we can pro&Characteristic of stainless steel mixing equipment* Contact part : SUS316L or SUS304* Function : heating, blending, homogenizing* Mixing system : frame scraper agitator mixer and high shear homogenizer mixer* Heating system : jacket heating / running water cooling* Movable design and simple to operateApplicable Products.1. Cosmetics industry: skin care cream, shaving cream, shampoo, toothpaste, cold cream, cold sun cream, facial cleanser, nutrition dense, detergent, shampoo, hair cream, conditioner, serum, moisturizing cream, Hand cream and so on.2. Daily chemical industry:Laundry liquid production, hand sanitizer, toilet net, car glass water.3. Pharmaceutical Industry:Latex, emulsion, ointment (ointment), oral syrup, oral liquid and the like.4. Food Industry:Sauces, cheese, nutritional liquid, baby food, chocolate, sugar and so on.5. Chemical Industry:Latex, Sauce, specified products, paints, coatings, resins, adhesives, lubricants and so nfiguration:1. Quick opening manhole.2. Various types of CIP cleaners.3. Sanitary ventilation hood to defend against flies insects.4. Adjustable triangular bracket.5. Detachable feeding tubes.6. Thermometer (According to the customer's requirements).7. Ladder (According to the customer's requirements).8. Advancing side blender9. Level meter and level controller (According to the customer's requirements).10. Anti-vortex andard mixing tanks or tailor-made for your product and processWe understand that every mixing tank is different. Therefor, we design our tanks tailor-made for you, so you can be sure that the tank will suiude into your tank are:* Tillable*Fully integrated control panel*Heated and/or cooled*Agitators*Load cells*Level switches*Cleaning options*Skid mountedFeatures:1. Inner tank body, jacket and outer layer, with thermal insulation material filled in between.2. Materials are all sanitary stainless steel.3. User-friendly design ,easy to operate.4. Transition area of interior wall on tank adopts arc for transition to ensure no deader of itator design and fabrication:In addition to tanks, We also make its own agitators. This way you have one point of contact for the entire tank concept. Agitators that we design and produce are:*Gate agitator*Anchor agitator*Scraping agitator*Propeller agitator*Bottom driven agitator*Dispersing disk*Rotor/stator*Screw agitator*Combination of agitators*High shear mixer*Turbo mixer*Side entry agitator*Static mixer*External homogenizerStirrer Inside The Tank We Have Different Types: Homogenizer, Paddle, Frame, Propeller, Anchor With Scraper ( Other Stirrer can be customized )1, Bottom magnetic agitator with propeller impeller, speed fromrpm orrpm. This kind of agitator is mixing thin viscosity, such as eye drop, injection, CIP liquid, water, etc.2, Top mechanical agitator with propeller impeller, speed at fix 71rpm or adjustablerpm or special requirement. This kind of agitator is mixing syrup, injection, blood, oral liquid, culture media, etc.3, Top mechanical agitator with anchor or frame impeller, speed is fromrpm. It is mixing higher viscosity, such as sediment or viscosity oral liquid, etc.4, Top emulsification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. This kind of agitator is mixing most high viscosity, such as suspension, oil, fat emulsification, etc.5, Bottom emulsification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. This kind of agitator is mixing most high viscosity, such as suspension, oil, fat emulsification, etc.We have more than one hundred different types of mixers to meet your product process.Application:1. Cosmeticand daily chemical product:Cosmetic cream, lotion, shampoo, detergent, health care product, gel, Laundry detergent, hand sanitizer, armpits lotion etc.2. Pharmaceuticalproduct:Ointment, Ice packs, injection liquid, penicillin etc.3. Food:Salad, mayonnaise, peanut butter, sesame butter, buttery, Animal fat, iced products, healthy food verage:Fruit Juice, Milk Juice etc.5. Chemical:Paints, Pigments, dyes, photo solvents, Rubber and resin, pesticides, Shoe polish, general chemicals tailed PhotosCertificationsPackaging & ShippingWe are experienced in the whole packing and shipping process,and we will be responsible for any damage made during shipping and send clients replacements for free.* Suffuding bubble bag, foam board and others.* Qualified wooden package or carton for different products or as customer require* Strict packing process to ensure the safety andpleteness of the goodsFAQQ1. What is your terms of packing?A: Generally, we pack our goods in a plywood case or carton package for small parts.If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.Q2. What are your terms of payment?A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.We'll show you the photos of the products and packages before you pay the balance.Q3. What are your terms of delivery?A: EXW, FOB, CIF, DDU.Q4. How about your delivery time?A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time dependson the items and the quantity of your order.Q5. Can you produce according to the samples?A: Yes, we can produce by your samples or technical drawings.Q6. Do you test all your goods before delivery?A: Yes, we have 100% test before deliveryQ7: How do you make our business long-term and good relationship?A:1. We keep good quality andpetitive price to ensure our customers benefit ;2.rely do business and make friends with them, no matter where theye from. nlXfoqEVUzdb

Get Price